Precision feeding in poultry

Precision feeding in poultry, or formulating diets as close to the bird’s requirement as possible is effective economically and environmentally. Homogeneity of nutrients, especially trace minerals because of their low inclusion rates, is critical for the success of precision feeding.

By CHRISTIAN BOIGUES, MIEKE ZOON and CÉLINE ROBIN

The trend towards more efficient production of food has a significant impact on animals production sector. Not only due to economic pressure, but also because of societies quest for reduction of environmental impact. At the same time, we have become more aware of the risks of using antibiotics as a means to improve efficiency due to the development of multi-resistant bacteria. And finally the welfare and quality of life of animals is a growing concern especially in the Western world. These challenges seem very different and sometimes even contradictory and a variety of solutions are suggested to improve either one of them. The concept of “precision feeding in poultry” is growing in popularity and could address more than one of these challenges.

Definition: Precision feeding in poultry

Precision feeding means feeding every animal according to its individual requirements. Not only on average, but every single day, and throughout the day. This is very much related to efficiency, as the closer nutrients are provided to the animal’s requirements, the more the animal is supported to use its full genetic potential. Providing less than its requirements for any important nutrient (e.g. energy, amino acids, vitamins, (trace) minerals) will reduce performance. Providing all the nutrients the animal needs, when it needs them, ensures optimal performance and limits the waste of nutrients. This is not only affecting input efficiencies but also welfare and health.

Precision feeding and uniformity

Uniformity of animals within a group is becoming increasingly important for producers. In many sectors production becomes more integrated and automated on large scale operations, a more uniform group of animals has many benefits.

For example, in broilers a uniform flock with the correct average bodyweight will grow more uniformly when provided the same feed and will reach the ideal slaughter weight (or close to it) on the same day.

This is very important for the increasingly automated slaughter houses which are designed to optimally handle specific weights, as well as for uniform final meat products. Bodyweight (BW) is not only important at slaughter, but also a main factor for onset of reproduction in breeding animals, such as the start of lay in poultry.

So how does this link to precision feeding in poultry?

More uniform animals have more uniform nutrient requirements. This makes sense because if animals are of similar size, age, breed, have similar performance levels and are kept in similar conditions, it is likely that their nutrient requirements will be close as well. Practically It is much easier to fulfill the individual requirements of animals if these are close to the group’s average.

The other way is the opposite and as important for producers and uniformity of animals and their performance over time. If precision feeding is applied well, it can improve animal uniformity. A heterogeneous group of animals in which the animals are provided with their individual requirements, will make the best use of their full genetic potential and their performance will be increasingly uniform. Precision feeding and uniformity in animals in addition to their performance is therefore very much interconnected, both as cause and consequence.

Mineral homogeneity in particles

One of the main challenges in precision feeding is the low inclusion of essentials nutrients like minerals. In fact, the inclusion level can be so low that the homogeneity of the distribution can be challenged.

Therefore, if it is not homogenous, animals won’t get all the nutrients needed. The latest development and new generation of multi-mineral products is B-Traxim All-in-j. Using Pancosma’s Iso-Fusion technology (IFT), every particle contains a combination of different minerals at the exact same ratio, for a perfect distribution and homogeneity in premix and feed.

Using Scanning Electron Microscopy associated with Energy Dispersive X-ray spectroscopy (SEM-EDX) at the Centre Suisse d’Electronique et Microtechnique (CSEM) in Neuchatel, Switzerland, it was possible to identify the four different minerals in one of B-Traxim All-in-j products. Minerals (Cu, Fe, Mn, Zn) were identified and represented with different colors. All four metals are present, not only in every particle, but very homogeneously distributed throughout every single particle.

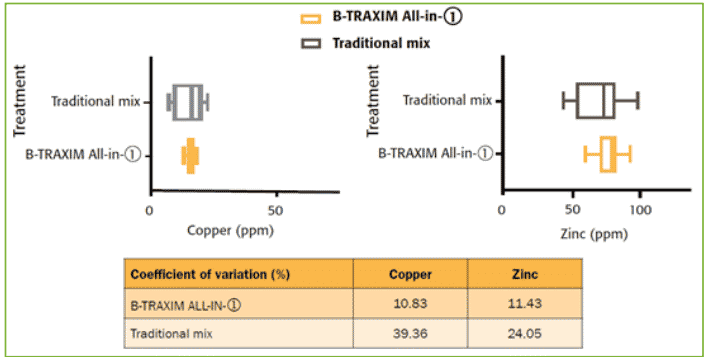

In the end, the final user is looking for homogeneity in providing nutrients and its effects on the uniformity in animals, their performance and products. A series of tests based on the coefficient of variation confirmed a much lower deviation to the mean with All-in-j products compared to traditional blends (Figure 1).

Figure 1 Homogeneity in feed – coefficient of variation of copper and zinc contents in B-Traxim All-in-1